- About us

- Technologies

- Services

- PR Center

- Careers

The World Leader inEnergy Plant TechnologyWe provide the best quality energy equipment with the best engineering and services.

- Technologies

- Supercritical Steam Generator

Supercritical Steam Generator

Steam Cycles for Power Generation

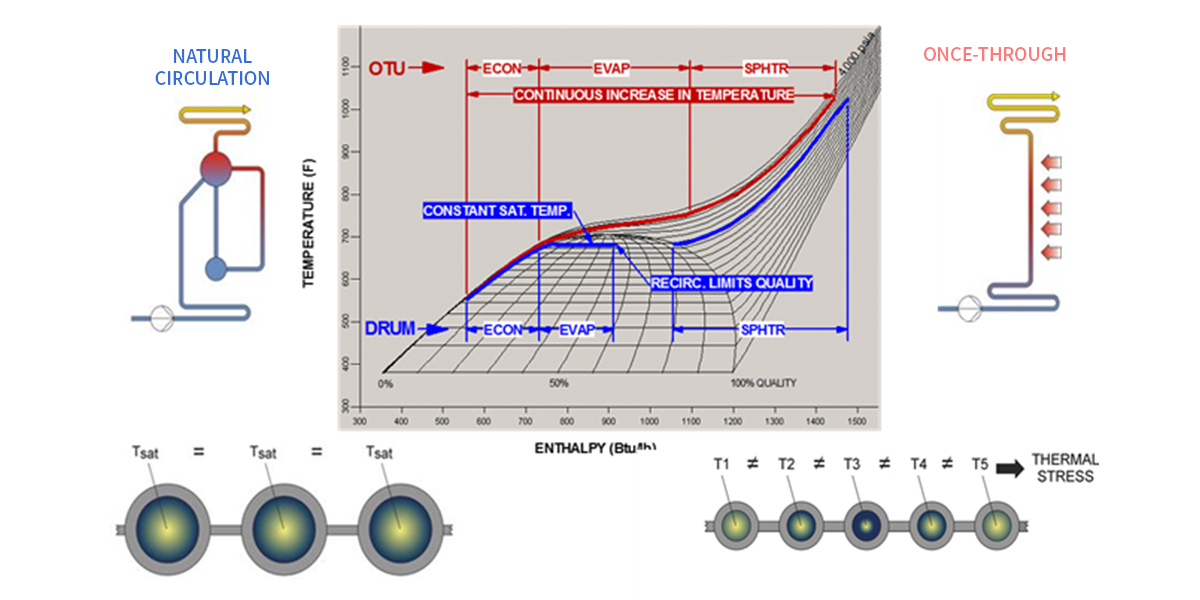

Steam cycles for power generation include the sub-critical cycle and the super critical cycle. The sub-critical cycle operates at pressures below the critical pressure of water/steam (22.11 MPa / 3206 psia), while the super critical cycle operates at pressures above the critical pressure. The critical pressure is the highest pressure where water and steam have distinguishable phases. Thus, below the critical pressure there is a distinction in the density of the steam and water; above the critical pressure there is no distinction. The differences to the process of generating steam with the two cycles are illustrated below.

Figure 1

The red line on the diagram represents the process at supercritical pressures. All of the water in the tubes of the furnace is turned into steam and the temperature of the fluid rises continually as heat is added. As the temperature of the fluid continues to rise, the temperature of the tubes continues to rise. Differences in heat absorption results in temperature differences from tube to tube.

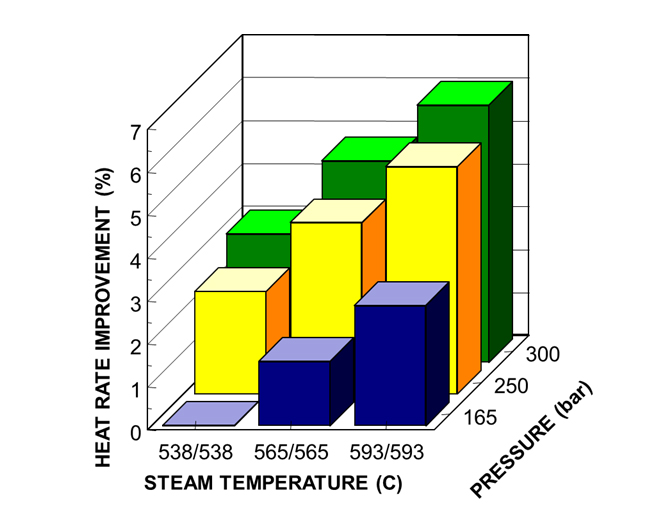

Note that most utility steam generators world-wide are of the drum type for the sub-critical cycle. While power plants operating at super critical cycles have been around for decades, the current focus on emissions from power plants have increased interest in the super critical cycle due to its better overall plant efficiency (net plant heat rate). See Figure 2.

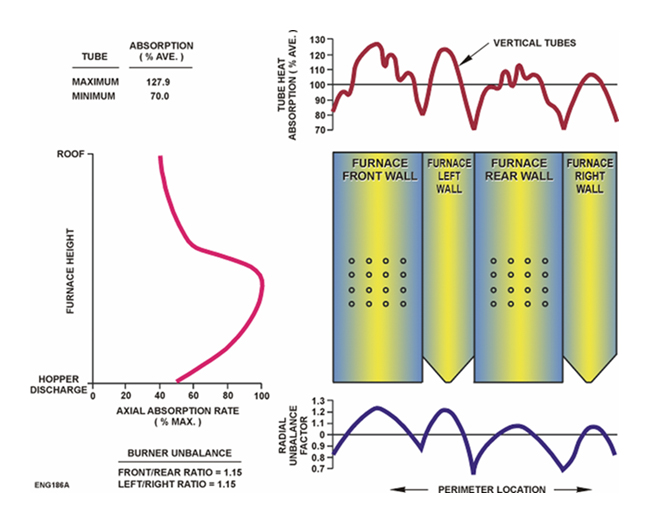

The steam generators for both the sub-critical and super critical cycles are subject to the same variations in heat absorption at different elevations and around the perimeter of the furnace. See Figure 3. Therefore, the designs of the steam generators for the two cycles need to address the evaporative circuits of the furnace very differently.

The design of a once through steam generator for super critical cycles targets a mass flow in the furnace wall tubes which will provide adequate cooling for the heat absorption rate. The cooling of the tubes is checked at multiple loads on the steam generator. If insufficient flow for adequate tube cooling is discovered at reduced loads, a recirculation pump is used to provide the needed additional flow to the furnace circuits.

-

Figure 2

-

Figure 3

Once Through Steam Generators

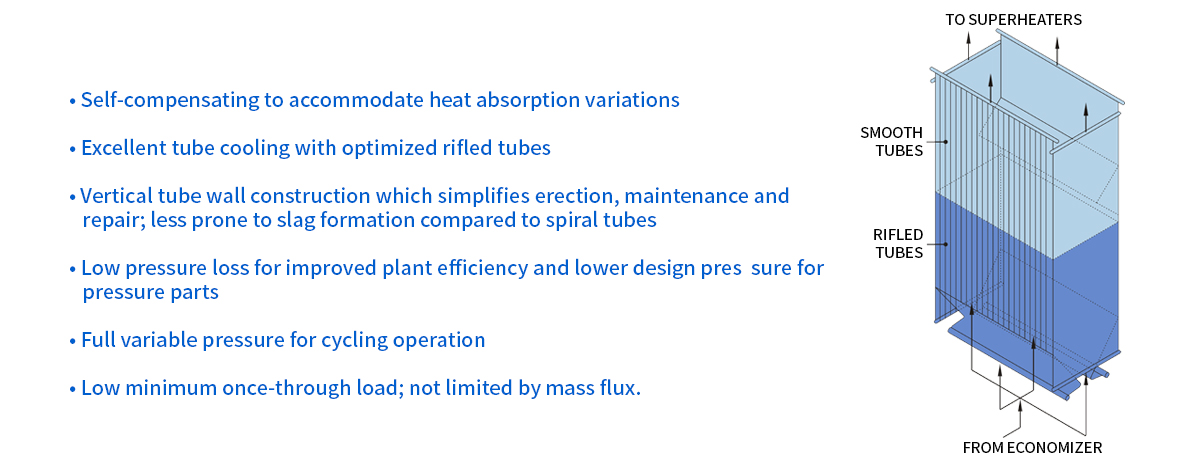

For super critical power cycles, the BENSON Vertical Tube (BVT) steam generator is the state-of-the-art design. The design uses vertical tubes for the furnace walls, which simplifies design, fabrication, erection and maintenance while providing reduced steam generator pressure drop yielding better cycle efficiency.

The BVT designs uses optimized ribbed tubing to enhance heat transfer in the furnace evaporator tubes. The enhanced heat transfer permits a lower mass flux for the same tube cooling. The low mass flow yields a self-compensating, natural circulation characteristic to the once through circuits; that is, the tube receiving higher heat absorption also receives higher mass flow thereby suppressing tube metal temperatures. See Figure 4.

Figure 4